Need an Inspection at your Location? We will assist you, at a very nominal cost, to identify critical zones that require minor or major installations based on our 30+ years of valuable experience. Please contact us to depute our personnel to your plant site for doing the needful.

KF 605

Fire Retardant coating for Fibre Reinforced Plastics (FRP)

Product Menu

KF 600

Fire Retardant coating for Fibre Reinforced Plastics (FRP)

2800/3000

9.81

Client Review Score

5/5

1k+

Projects Completed

Successfully

Our environmentally friendly, water based Fire Retardant coating is designed to retard /prevent the propagation of fire along the cable runs and reduce the hazards of toxic fumes. It provides the time required to fight the fire and in the meanwhile assuring short term integrity, which enables the other active systems to perform with ease. Thus the fire is checked in the occurrence stage itself. It is added that our Fire Retardant coating is installed / applied on electrical cables already laid in your Plant.

Fire needs three basic elements to start. This is called the fire triangle. If any one of the three elements is missing, fire will not ignite, or, if it is already burning, removing one of the three will quench the flames. The three elements are:

- FUEL: Fire needs something to consume. Fuel can be a solid, a liquid or a gas.

- OXYGEN: Fire needs oxygen to burn. An atmosphere with less than 16% oxygen will not allow a fire to burn.

- HEAT: Without energy needed to burn, flames die.

- RE-ENTRY HEAT: Heat arising from burning cables that, in turn, pre-heats cables stacked above. Pre-heating causes cable insulation to degrade and emit flammable fumes to assist in spread of fire.

- RADIATIVE HEAT: The heat radiating downward from the flame that causes continued heating and decomposition of cable insulation.

- Functions by limiting the oxygen drawn from the atmosphere, thereby inhibiting the combustion and heat build-up process in the immediate vicinity of the cable insulation.

- The coating converts the bunch of cables into one coated cable and compartmentalizes an uncoated fire zone from the coated non – fire zone.

- Dissipates the heat generated by the fire and thereby prevents heat conduction.

- Water based viscous compound consisting of thermoplastic resins

- When coated on electrical cables it prevents propagation of fire along horizontal and vertical cable runs

- Restricts fire propagation caused by internal short circuit and keeps the cable functional for a considerable amount of time

- Does not affect the current carrying capacity of the cable, thereby derating not required

- Mechanically strong, can withstand foot traffic and drop loads

- HALOGEN / ASBESTOS FREE

- Reduces additional emission of corrosive gases / fumes by suppressing fire

- No imported inputs

- Maintenance free

Technical Data

Technically Sound

KF-605 Fire Retardant coating for Electrical cables is a 100% indigenous fire retardant with various benefits.

- Drying Time : 30 – 60 mins per coat depending on ambient condition

- Flexibility : Passes: no cracking

- Water / Acid / Alkali / Oil : No effect

- Covering Capacity : 2.8 to 3 Kgs per sq. mtr. to an approximate thickness of 1.8 mm to 2.0 mm (DFT)

- Fire Survival : Passes ( As per IEC – 331)

- Fire Retardancy : Passes (As per IEEE – 383 & IEC – 332 )

- Ampacity : De-rating not required

- Ageing : Passes ageing test for 168 hours at 800 C and 2 hours at - 100 C

- Water Immersion : No effect after immersion for 360 hours

- Radiation : No effect

- Flash Point : Nil

- Effect on cable jacketing mtrl. : No effect.

- Physical Properties – Ph – 6 to 8, Odourless, touch dry – 45 mins; hard dry 72 hrs

- Flammability as per IEEE – 383 / 10810-Part 53

- Fire Survival as per IEC – 331-21 (One hour)

- Flexibility, adhesion as per IS – 101 and IS 10810 Part 50

- Current Carrying Capacity. (Ampacity and Insulation test)

- Anti Termite / Anti Rodent

- Toxicity as per IEC – 754. (Halogen Content)

- Limiting Oxygen Index as per ASTM – D 2863-1991

- Flame Propagation as per IEC 332-3 Category A

- Heat Ageing as per IS 5831

- Test for Asbestos content

- Chemical Resistance Test

- Oil immersion test

- Water Immersion Test

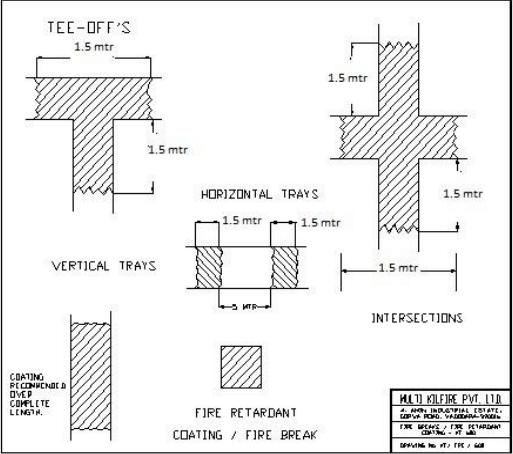

- In vertical and horizontal cable runs, tee-offs, intersections, cable crossings, cable joints etc.

- Where vertical trays pass through grated floors or

other floor penetrations where penetration fire seals are not practical. - Cables in boiler / oil lubricant storage areas, battery rooms and oxygen plants to name a few.

- Cable under false flooring where fixing of penetration seal is not practical.

- Cables affected by coal / lignite dust deposits.

- Cables affected by chemical fumes, acid and hydrocarbons.

- Functions by limiting the oxygen drawn from the atmosphere, thereby inhibiting the combustion and heat build-up process in the immediate vicinity of the cable insulation.

- The coating converts the bunch of cables into one coated cable and compartmentalizes an uncoated fire zone from the coated non – fire zone.

- Dissipates the heat generated by the fire and thereby prevents heat conduction.

- Keep 5 to 10 mtrs interval between coats in Open locations.

- Although 100% coating is recommended to enable Fire Fighting personnel to speedily approach the seat of fire, due to economic considerations it is advisable to maintain atleast an interval of 2 to 5 m in cable galleries, underground locations and cable tunnels where cable runs are congested and visit of company personnel to site is inconvenient.

- 100% coating in critical areas like coal mills etc.

- Vertical cable runs should be protected by coating the entire length.

- Open the Packet/Drum containing the coating and thoroughly stir the contents to achieve a uniform and homogeneous mix. If material is not stored properly and packaging is exposed to heat, you may find a rough paste kind of consistency. Thoroughly mix, and if required add some clean water to achieve desired density/viscosity

- Dip a standard brush (2”) lightly and apply a thin stretched coat called as the misting coat. This is the most important coat as this will create adhesion for the subsequent coats, and help you achieve maximum qualities and properties of the product.

- Allow the coat to dry for about 15 minutes or till you achieve touch dry effect

- Now take a heavy dip and apply the 2nd coat. For this coat the brush must not be stretched too much. The brushed must be dabbed on the surface in-order to achieve thickness in the coating.

- Repeat above process for the 3rd and 4th coat maintaining a drying time interval of 30 to 60 mins between coats depending on the ambient conditions. After each coat the material should have the touch dry effect (where-in material should not stick on hand while touching it)

- Normally Misting Coat plus 2-3 coats are substantial, but due to variations in viscosity depending on the ambient conditions and application methods to achieve a DFT of 1.8mm to 2mm thickness it may be required to apply (with brush) at least 3-4 coats after misting coat.

- To achieve a hard dry status, we recommend a drying period of 72 hours in ambient conditions. (Minimum 168 Hours required for Complete curing of Coating)

- Please note: once a packet/drum has been opened, consume at once, do not store for later application as the material will dry and lose its properties. It is recommended to open 1 packet at a time during application

NOTE: PLEASE DO NOT STORE MATERIAL IN THE OPEN

It must be placed in a covered shed to avoid drying up and damaging of material inside

20 Kg HDPE Drums

STORAGE:

Please store the product in covered area and not exposed to direct sunlight or heat as the product is water based and may dry up, losing its adherent properties.

Click here to download the MSDS.

Fire Rating

KF-600's Fire Rating

We, at Multi Kilfire, go to extreme lengths to test our products and adhere to Industry Standards.

- Fire Retardancy as per IEEE –383

- Fire Survival as per IEC – 331

- Flammability as per IS – 10810 part 53 / IEC 332

- Hydrocarbons and chemical exposure

- Flexibility, adhesion as per IS – 101

- Current Carrying Capacity

- Anti Termite / Anti Rodent

- Toxicity as per IEC – 754

- Limiting Oxygen Index as per ASTM – D 2863

- AGEING TEST

- AMPACITY & INSULATION

- ANTI RODENT TEST

- ASBESTOS TEST

- CHEMICAL RESISTANCE TEST

- Flame test IEEE 383 ERDA

- FLAMMABILITY - 120 MINS

- FLAMMABILITY TEST

- FLEXIBILITY & ADHESION

- GAS GENERATION TEST

- IEC 331 - 21

- IEC 331-1970

- IEC 332 - 23

- IEEE383

- METCHECM Guj. Govt. Approval Certi.

- OIL IMMERSION TEST

- OXYGEN INDEX TEST

- PH - ODOUR

- TEMPERATURE RESISTANCE

- WATER IMMERSION TEST

More...

Learn more about Multi Kilfire products

To learn more about Multi Kilfire products please follow the links below.

Learn more about Multi Kilfire's Test Certificates

We, at Multi Kilfire, go to extreme lengths to test our products and adhere to the following Industry Standards.

Learn more about our Inspection Reports.

We have completed over 2,000 projects. Some work completion certificates can be found here.

Click here to see a list of some of the clients we have successfully installed MultiKilfire products.